Any untreated material made with iron exposed to oxygen and water will rust. Since steel is almost completely made of iron, it’s the most highly man made material that is subject to rust.

When steel rusts, it undergoes a chemical reaction called corrosion. How quickly steel will rust depends on how much of the steel is exposed to moisture and air, the level of moisture and air, and whether or not any rust inhibitors are used.

Rusting will affect the outside of the steel before corroding through the steel surface. Therefore, it is important to have a protective coating to shield your metal from rusting. Galvanizing, the process of applying a protective coating to steel or iron, is important because it can provide long-lasting protection for products.

Galvanized coating is made from zinc and used to stop the formation of rust by preventing corrosive substances from reaching the metal underneath.

There are many benefits to using galvanized products for your steel building, including:

- Saving money: While it may seem expensive at first, treating your steel building with a rust inhibitor can save you money. You won’t have to replace any parts of your building due to rust damage and save money on overall maintenance costs.

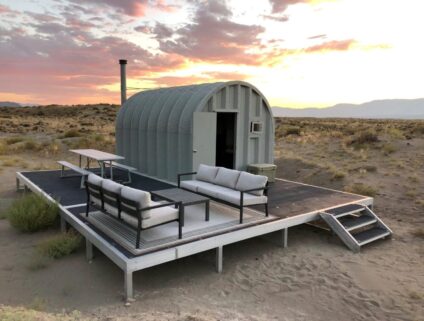

- Little-to-no maintenance: An anti-corrosion agent will help upkeep the appearance and safety of your Quonset hut.

- Long-lasting: You can increase your building’s life expectancy for decades by protecting it from rust with a galvanized coating, especially if your building is located in a harsh environment.

There have been many advancements with galvanization since it was first introduced in 1836. For example, the organic coating Galvalume Plus combines both aluminum and zinc alloys for maximum protection, making it highly corrosion resistant against rust.