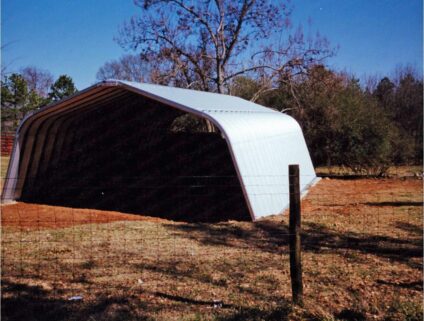

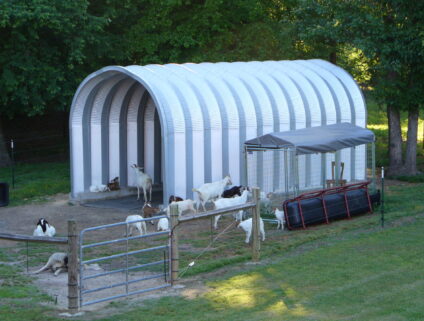

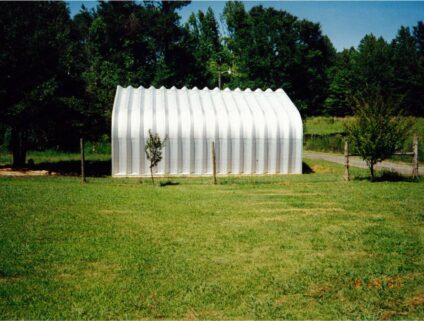

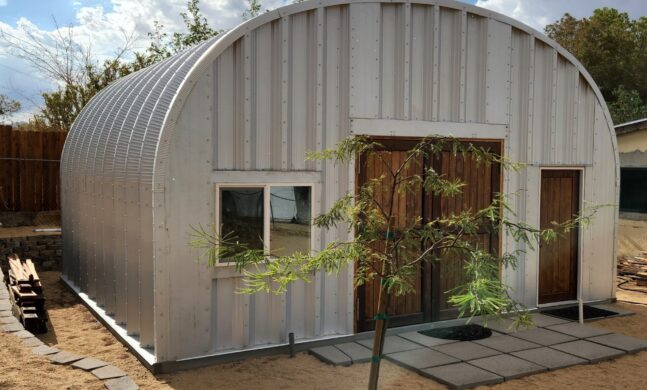

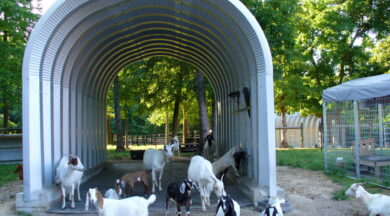

Protect your harvest, livestock, or expensive farm equipment inside a durable SteelMaster metal Quonset Hut barn. What’s the right style for you? Check out some of our favorite steel barn projects.

Barns

industry leader in metal Quonset Hut barns

Agricultural industry professionals and residential property owners love our barns because of their initial affordability and long-term cost savings.

Most Popular Barn Sizes & Pricing

Most Popular Uses

Quonset vs. the Competition: Pricing & Construction

Agricultural industry professionals and residential property owners love Quonsets because of their initial affordability and long-term cost savings.

Barn prices compared

| Barn Type | Price Per SqFt |

|---|---|

| Cheap pole barn | $4 – $10+ |

| Quonset steel barn* | As low as $11 |

| I-beam steel barn | $13 – $22+ |

| C-channel steel barn | $14 – $23+ |

| Traditional wood barn | $25 – $29+ |

The cost of labor and materials needed for a traditional wooden barn makes them among the more pricy solutions to farm storage. This is especially true when compared to pre-engineered metal farm buildings where the price per square foot can be as little as half in some cases.

While I-beam and C-Channel barns provide excellent options they are much pricier than a Quonset barn that provides the same, if not better, storage protection for agricultural goods.

“Cheap” storage can solve the short-term problem of keeping things like hay or farming equipment safe from the elements but should be seen as they are intended – as a temporary solution.

A Quonset hut barn can cost a little more than a cheap pole barn yet provides an excellent permanent solution to farm storage. This makes Quonset barns one of the most cost-effective choices when evaluating metal farm building prices.

Construction costs

Both pole barns and Quonset barns are faster to build than traditional barn buildings, which saves money on labor and construction costs. However, Quonset huts have the extra advantage of being prefabricated and not requiring any special skills or tools to complete.

| Barn Type | Construction Time |

|---|---|

| Quonset barn* | 1 week or less |

| Pole barn | 2 – 4 weeks |

| Traditional barn | 4 – 6 weeks |

Long-term building costs

When purchasing a barn kit, with or without the pole, an important factor to consider is long-term versus short-term costs. Compared to a Quonset, the maintenance costs of cheap pole barns or wooden barns are extensive and expensive.

Customer Howard Arnold is pleased with the durability and affordability of his Quonset-style barn. So far, he has not had to do any maintenance to the building since tightening the last bolt.

“Zero maintenance to the barn up to this point and hopefully from forevermore,” Howard said.

| Pole Barn | Quonset Barn | |

|---|---|---|

| Impact damage repairs |

|

|

| Re-roofing |

|

|

| Painting |

|

|

| Wood rot |

|

|

Cost factors & customizations

Typically, steel barns start as low as $11 per square foot with several factors impacting the final cost. The larger a barn is with more custom features, the more expensive the final building will be.

Simple animal run-ins or equipment coveralls are the cheapest options because they only consist of the steel arches you assemble and erect. If you need protection beyond shelter from the elements, you’ll want to consider these common barn-building customizations and size options.

Three popular customizations include:

- Endwalls (optional)

- Size

- Climate control/ventilation (optional)

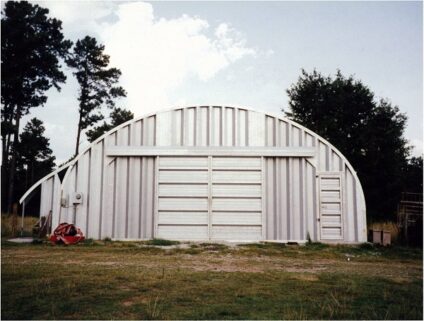

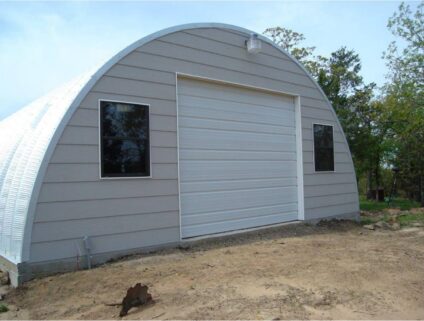

Barn endwall configurations

Depending on your needs, your barn can have two endwalls, one endwall, or no endwalls.

Metal barn sizes

SteelMaster’s building specialists will help you find a barn that fits your budget and size requirements.

Climate control needs

Should you insulate your Quonset hut barn? The short answer is…it depends. The control of the temperature or air quality can depend on several factors such as what you store inside and where your building is located.

Our steel barn kits are easy to build

Every steel panel of your Quonset barn kit is pre-drilled and pre-punched — the entire building only requires one size nut and one size bolt. All you need are a few tools, a few friends, and a few days to put together your SteelMaster Quonset Hut.

Pre-construct your arches

Lay the arches of the building out on the ground and hand-tighten each panel together. You’ll want to decide if you’ll be raising the entire arch or half of an arch at a time and pre-construct the arches accordingly. For larger buildings, it often makes sense to raise a half arch at a time.

Raise & connect the arches

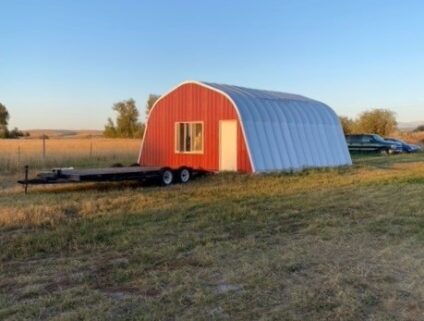

Now that the arches are mostly assembled on the ground, raise each of them, and connect them to any foundation you need — our arches can be put on shipping containers, on the ground, or anchored to a concrete foundation. Then, connect the arch to the previously raised arch.

Tighten the bolts as you go

Once four arches are up, go back and fully tighten the first arch. Then each time you raise a new arch, go back and tighten the arch that’s four arches back.

Install endwalls

Now that the building has been erected, install the endwalls you’ve selected for the barn. A popular option is to use steel endwalls provided by SteelMaster as they are functional and economical.

The time each of these steps will take depends on your construction experience and any help you have during construction. Many barn kits we sell are erected in as little as three to seven days.

Pole Barns vs. Quonset Barns

Do you even need a pole? In traditional pole barns, wooden poles are buried in the ground and used as columns for the roof. The walls of the pole barn can be made of wood, or sometimes tin, and screwed or nailed into the poles.

Pole barns are typically not engineered to meet structural requirements because they’re not thought of as permanent structures in some locations due to the lack of foundation. The poles of a pole barn are used for structural support, which is great for keeping the barn from collapsing, but terrible for usable space on the interior.

Ideally, you’d want to ditch the pole, to maximize movable space and maneuverability within the barn, but keep the portability of a pole barn. Quonset “pole” barns are structurally sound and provide 100% usable space without beams, trusses or poles inside and can still be disassembled and reassembled anywhere on your farm or property if need be.

| Pole Barn | Quonset Barn | |

|---|---|---|

| Clear span |

|

|

| Expandable |

|

|

| HVHZ impact rated |

|

|

| Up to 190 mph winds |

|

|

| Prefab construction |

|

|

| Portable |

|

|

| Maintenance costs |

|

|

The Ultimate Guide to Quonset Barns

Check out real-life SteelMaster projects & learn more about:

- The features and benefits of arch style buildings for barns

- Step-by-step arch construction

- Technical specs & certifications

Get Inspired

We hope some of our customers’ most impressive projects will inspire you to get started on your own Quonset hut structure. See all articles.

40+ years of designing metal barns

Get a free project quote

Form Capture Name in CRM: English - Residential Product Page Form

"*" indicates required fields

By adding my phone number, I agree to receive recurring text messages at the phone number provided from SteelMaster Consent is not a condition to purchase. Carrier & data rates may apply. Message frequency may vary. Reply STOP to cancel. Reply Help for more information. View our Terms of Service for details.