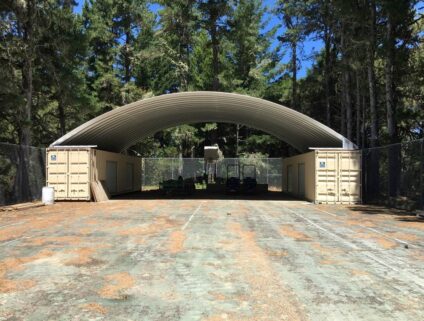

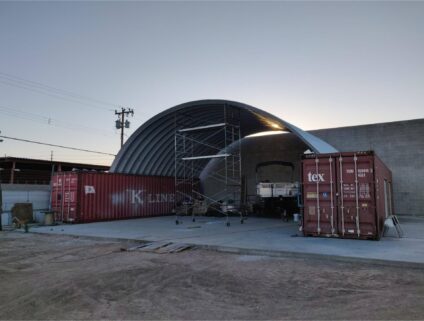

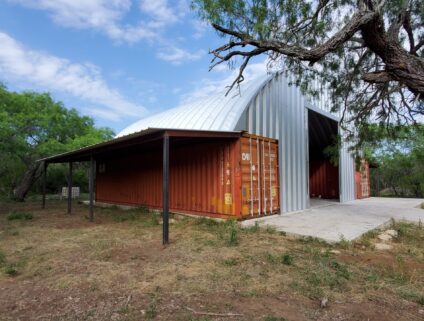

Container Roof Mounting Options

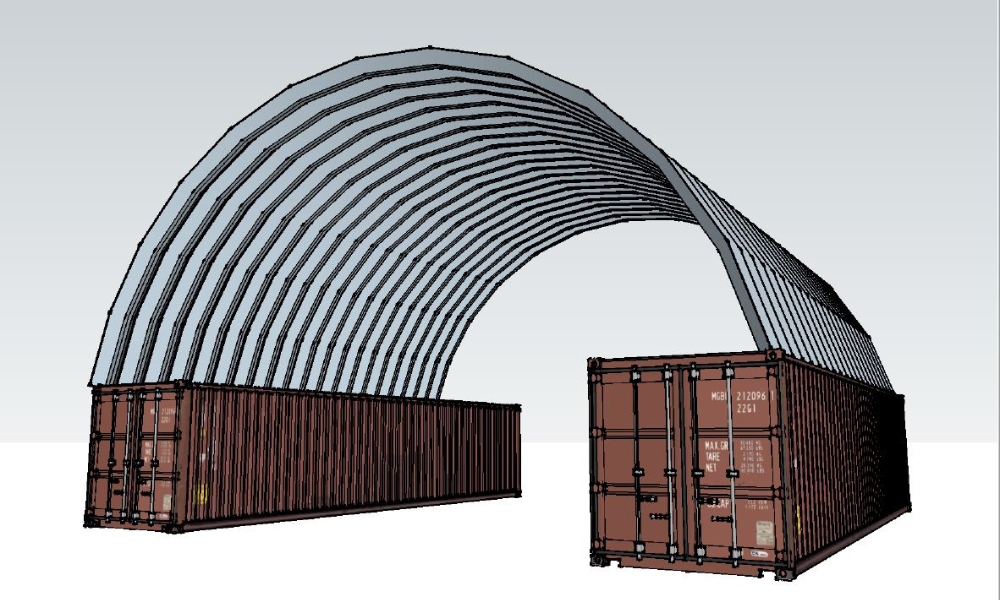

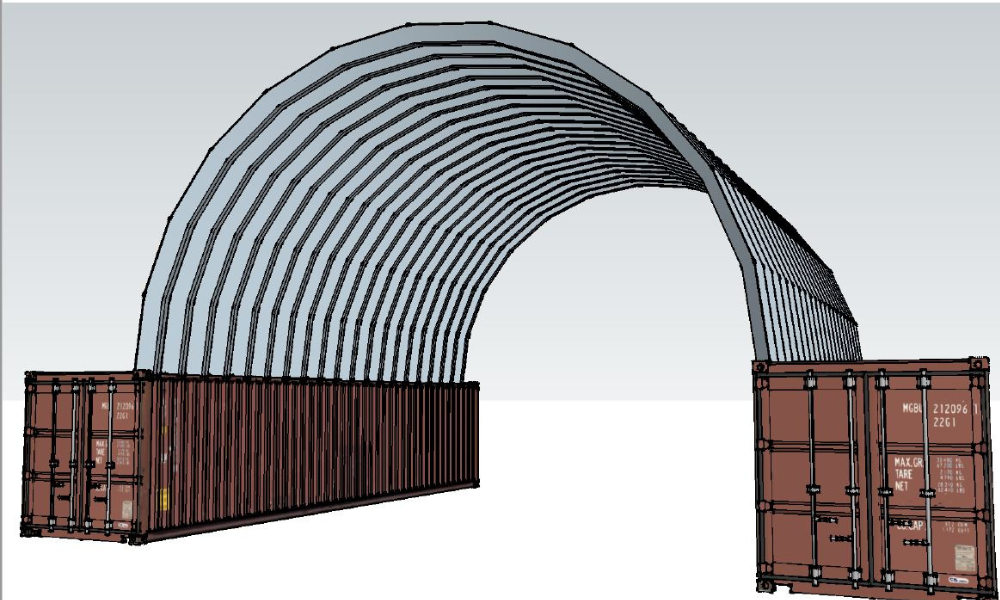

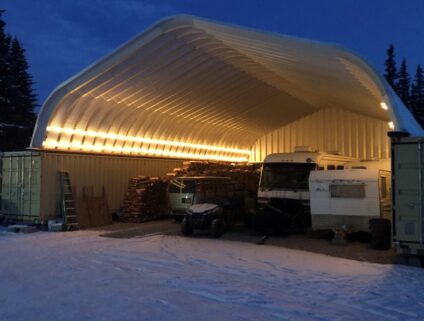

Roofs can be attached to either the inside edges or outside edges of the two containers, referred to as “inside mounts” and “outside mounts.” For the largest industrial-scale projects builders can also mount a roof on top of stacks of two shipping containers.