Three Common Misconceptions About Steel Buildings

When purchasing a steel building, it’s important to take the time to do your research. There are many myths and misconceptions about Quonset Hut™ style steel buildings, and we’re here to put them to rest.

Misconception #1: Steel buildings are difficult to put together.

While the design concepts of our buildings may seem complex, they’re actually quite easy to put together. Virtually anyone can take a simple SteelMaster building kit and build any kind of structure the imagination can dream up. One of the many advantages of a SteelMaster Quonset Hut™ is that they are do-it-yourself and can be assembled by you, the purchaser. Over eighty percent of customers construct their own building, resulting in huge labor cost savings. Seventy percent of the work is done on the ground with only one-size nut and bolt.

One Texas couple wanted their own home, but they never dreamed of building it themselves! Linda Mulkey’s husband, Dennis, created his own tools and even came up with a unique system to help raise the arches. They hired crews to help them with the concrete slab and spray foam insulation, but Linda says Dennis did about 90% of the work on his own.

In most cases, no heavy equipment is required when raising your steel building. However, the help of a contractor may be needed when assembling larger buildings. SteelMaster customer Miguel Jimenez hired a crew to build a garage for his company in San Antonio, Texas. Four people from a welding company were able to assemble the building in just three days. Miguel said the crew never assembled a SteelMaster building before this project and were very impressed with how easily the building went together.

Misconception #2: All steel Quonset Huts™ look the same.

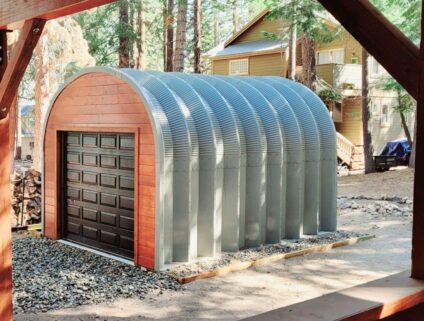

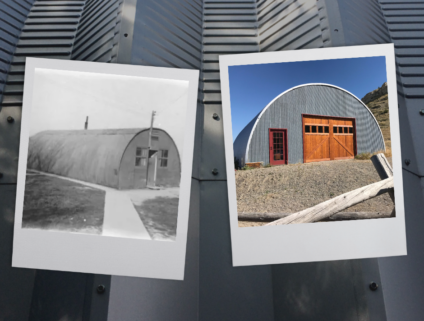

Most Quonset Huts used by the military in the 1940s had an industrial look, but that style has certainly changed since the World War II era! There are several ways to customize your steel Quonset Hut. While some people opt for the classic all-silver look, many people use custom endwalls to give their buildings some pizzazz. With custom endwalls, you have the ability to make your building match your home or any other surrounding buildings. Endwalls can be created from any material including vinyl siding, brick, or wood. Since the endwalls are non-load bearing, your custom design will only enhance the appearance of the building.

If you plan to add endwalls to your building, you’ll also need to add a door. Many of our customers add garage doors and/or service doors. We offer sectional overhead doors, frames for bi-fold doors and rolling sheet canister doors. We also offer basic service doors. They can be added for ease of access and placed in either a sidewall or an endwall.

Misconception #3: Steel buildings rust easily.

You may have seen other steel buildings become rusty due to corrosion or exposure to harsh elements. However, SteelMaster uses a coating called Galvalume Plus that helps to prevent rusting and basic wear and tear on the arches. This will significantly decrease maintenance costs as long as you own the building. Each steel panel is corrugated, adding even more strength to the entire structure. On top of that, we back every building with a 50-year warranty.

If you have any additional questions or concerns, don’t hesitate to contact a SteelMaster design specialist!

Categories