Al Harris, president of California-based Cube Depot, is renowned for offering his customers unique options for customizing shipping containers into ideal storage, office, or housing units. Driven by a spirit of innovation, Harris wanted to solve the problem he and his customers had of needing a large amount of space in a short amount of time and only having a few shipping containers to do so. His customers needed a solution that was:

- Quick to assemble/disassemble

- Expandable if needed

- Covers a large amount of square footage

- More durable than fabric, wood, tin or aluminum

SteelMaster Creates The First Steel Container Cover Roof Kit

Harris realized the potential that a shipping container posed to maximize storage, so he and his team began research for cost-effective roofing systems. They turned to SteelMaster, a prefab steel arch industry leader with decades of experience designing and delivering steel roofing systems to collaborate. Through this collaboration, Harris and SteelMaster developed the shipping container cover kit, adding a roof and using the extra storage space between two shipping containers in 2004.

For Harris, he needed a massive amount of secure storage space in a short amount of time which presented the SteelMaster team with some unique challenges. After working through the engineering and logistics of building the first container cover with Harris, SteelMaster has become an industry leader in container cover roofs and people all over have taken advantage of this innovation. Here’s how the steel container cover concept first came together.

The Problem

• Shipping containers make for tremendous walls and interiors of a building, but Harris and his team needed a durable but affordable roofing solution to cover the span between them.

• The shipping containers were double stacked, so a minimum 25-foot vertical peak height was required making other roofing options not applicable.

The Solution

• A team of SteelMaster design specialists developed a unique container roofing system, sacrificing neither design nor cost efficiency.

• SteelMaster’s design consists of a roofing system that covers two existing shipping containers.

The Execution

• The roof connected on the outside edge of one side while connecting to the interior corners of the other, providing stability for the large roofing system.

• Final measurements were 60’ long by 60’ wide and the roofing system was made with a 9’ apex, giving the 25’ vertical clearance required.

The Results

• SteelMaster’s concept coupled with Cube Depot’s innovation proved to be such a success that it made sense to consider it a prototype for future endeavors in this type of building.

• Not only was the project cost-efficient, but it held up to design expectations and created a very rugged structure that was pleasing to the eye.

• Cube Depot went on to build two more container cover storage buildings in Santa Barbara and Los Angeles.

SteelMaster and Cube Depot both believe that the greatest strength of this idea lies in the partnership of the two organizations. With an ultimate goal of shrinking the construction timeline through their partnership, SteelMaster and Cube Depot hope to dive even deeper into this exciting new idea in the future.

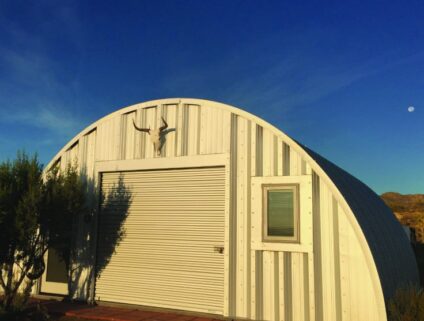

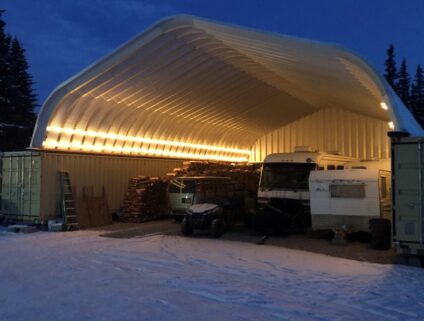

Today, the idea of utilizing container covers has continued to evolve with warehouses, barns and equipment storage being some of the most popular applications. SteelMaster customers from all over the globe are using container covers to create storage, garages, workshops, and more!

Categories

Tags

Related articles

Man Builds Container Cover Structure for Additional Storage

Container Cover Provides Functionality to Charleston Business

Container Cover in Alaska Offers an Affordable, Durable Solution

Hawaii FBO Upgrades Maintenance Shelter with Container Cover Building

Wisconsin Diner Uses SteelMaster Container Cover to Create Taproom

Shipping Container Storage Tips: 5 Ways to Maximize Storage

9 Questions to Ask Before Starting A Container Project

Company Uses SteelMaster Container Cover for Workshop

Hog Heaven: Home of Wild Pigs, a Coffee Farm, and a

Container Barn