The Anatomy of a SteelMaster Building

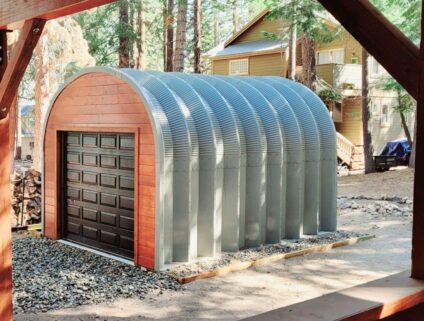

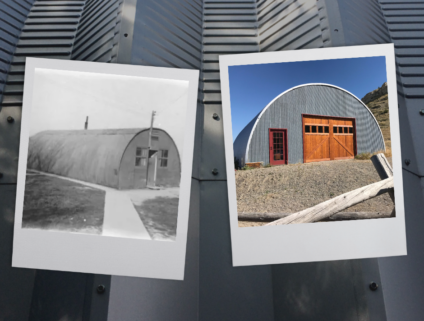

What makes a SteelMaster Quonset Hut one of the strongest buildings in the world? Here at SteelMaster, we re-imagined the arch and combined it with commercial-grade steel to increase durability and quality.

Several different types of panels on our arches overlap to give it that smooth, continuous curve all while maintaining its classic look.

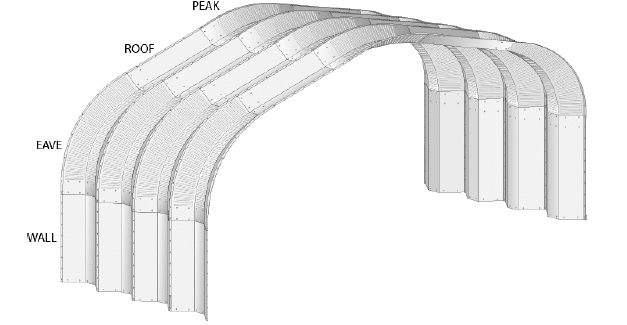

Let’s start with the peak of the arch, the highest portion of the structure. There are two types of panels to choose from, each with a slightly different peak. Type I panels have a wider curve at the peak, while Type II panels are a little smaller and have a steeper arch.

Bolted to the peak of the arch is the roof. While traditionally styled buildings are subject to roof collapse, our arches are designed to evenly distribute pressure from heavy snow loads or strong winds. According to the National Oceanic and Atmospheric Administration (NOAA), snow on the ground weighs roughly 33lbs per square foot. Typically, traditional buildings can handle about 20lbs per square foot of snow and it is recommended to remove anything on the roof exceeding 18 inches.

This is not the case for our Quonset Hut™ buildings. We follow the snow load provisions that the ASCE 7-95 and IBC require, as well as any area-specific codes in order to sustain the heavy weight. The two most important factors to consider when designing a building in a snowy area are the slope and pitch of the roof. Our X-Model’s 4:12 pitched roof makes it much easier for the snow to slide off on its own.

The roof overlaps with the eave, which is designed to throw water away from the wall. If a side service door is desired, oftentimes the eaves and the wall panels of two adjacent arches are replaced with the door.

Lastly, the eave panel is attached to the wall panel. Objects can easily penetrate the walls of traditional buildings during strong winds. However, when the same objects come in contact with a SteelMaster building, the object usually only makes a small dent. We tested the projectile penetration of our structures in strict accordance to FEMA 320/361 and ICC-500 by hurling a 15-pound 2” x 4” at 100 mph toward the steel wall. This was to simulate the winds in a powerful storm, and the building sustained minimal damage.

Each model has a unique combination of these components. A-Model Quonset Huts are designed with straight wall panels, curved eave panels, a straight roof panel and a curved peak panel.

The Q-Model Quonset Huts are a semi-circle, where the wall panels, eave panels, roof panels and peak panels are all curved to the same radius.

S-Models have straight wall panels, sharply curved eave panels, and slightly curved roof panels.

X-Model Quonset Huts™ are similar to the A-Model, but instead of having vertical wall panels, the X-Model’s wall panels are slanted.

Each of our buildings can be customized with anything from endwalls to light fixtures and the uses are virtually limitless.

Contact us today to get started on your perfect steel building!

Categories